Used by automotive OEMs and catalyst companies. Applicable for diesel vehicle exhaust upgrades, replacement parts, and non-road machinery emissions control.

1.Cordierite Particle Collector (DPF)

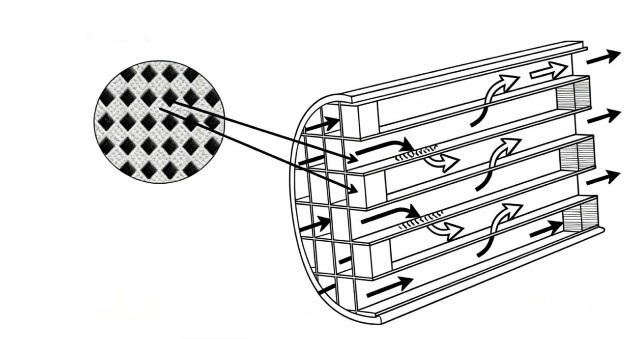

This product is made of cordierite and features a special structure of wall-flow porous ceramic filter body, which has advantages such as high porosity, large specific surface area, low back pressure, small coefficient of thermal expansion, and good thermal shock resistance. It is widely used in diesel engine exhaust purification devices for passenger cars, city buses, highway trucks, mining operation vehicles, and forklifts. By alternately blocking the holes at both ends of the honeycomb ceramic, it effectively captures the particulate matter discharged from diesel engines using the pores on the hole walls, purifying the exhaust of diesel vehicles.

| Cordierite Diesel Particulate Filter(DPF) | Performance Specifications | ||||

| Pore Density(cpsi)/Wall Thickness(mil) | Diameter | Height | Coefficient of Thermal Exp. (10-⁶/℃) | Soft temperature/℃ | Isostatic Strength/Mpa |

| 200/12 | 5.66"~13" | 6"~17" | ≤1.5 | >1300 | >1.0 |

| 200/12 | ≤0.7 | >1430 | >1.0 | ||

| 300/9 | ≤0.7 | >1430 | >1.0 | ||

| 300/9(Non-road T4) | ≤1.0 | ≥1360 | ≥1.0 | ||

| 300/9-ACT | 5.66"~12 | 6"~12" | ≤0.7 | >1430 | >1.0 |

2.Silicon Carbide Particle Filter (SiC-DPF)

This product is made of silicon carbide. Unlike cordierite DPF, the silicon carbide DPF has a higher upper limit for high temperature tolerance. During regeneration, it is not easily softened or sintered even if there is localized overheating, making it suitable for high-load exhaust scenarios. The thermal conductivity of silicon carbide particle filters is extremely high, allowing heat to quickly dissipate throughout the entire filter, thus avoiding excessive local temperature differences. Under actual complex working conditions, the thermal shock stability is even better. Additionally, silicon carbide DPFs have strong impact and wear resistance, making them suitable for commercial vehicles operating in complex road conditions. Besides on-road vehicles, silicon carbide DPFs are also used in non-road applications such as construction equipment, agricultural machinery, and mining vehicles, which often operate under extreme conditions. Due to its durability and heat resistance, silicon carbide has become the material of choice.

| Silicon Carbide Diesel Particulate Filter(SiC-DPF) | Performance Specifications | ||||

| Pore Density(cpsi)/Wall Thickness(mil) | Diameter | Height | Coefficient of Thermal Exp. (10-⁶/℃) | Soft temperature/℃ | Isostatic Strength/Mpa |

| 200/12 | 5.66"~13" | 6"~17" | 4.8±0.7 | ≥1500 | ≥1.0 |

| 300/9 | 4.8±0.7 | ≥1500 | ≥1.0 | ||

| 300/10 | 4.8±0.7 | ≥1500 | ≥1.0 | ||

| 300/10-ACT | 5.66"~12 | 6"~12" | 4.8±0.7 | ≥1500 | ≥1.0 |

| 300/12-ACT | 7.5 | 5"~6" | 5.0±0.7 | ≥1500 | ≥1.0 |

Please fill in the form with your details so that we can understand your product requirements.

One of our experts will contact you to discuss the most effective solution and estimated delivery time.

You will receive a detailed quote and an accurate timeline.

Contact Aofu

Get in touch with our experts!

A self-owned brand enterprise specializing in the research and development and industrialization of air pollution control products

Copyright © 2025 Shandong AOFU Environmental Technology Co., Ltd.

Design by:Bontop